A Federating Project for People with Disabilities

Last May, Polytech Sorbonne engineering students presented their flagship projects to more than thirty industrialists. Among their successes, the robotized adaptation of a workstation in partnership with the Sorbonne University's Disability Services.

The project began in 2018 when a laboratory technician suffering from a chronic disabling disease saw her troubles worsen due to the repeated manipulations she had to perform for an experiment. The neurobiologist, Elise Morice, who was supervising the study, asked the head of Disability Services, Eric Lalanne, to find a solution. "I contacted the director of theIntelligent Systems and Robotics Institute (ISIR), Guillaume Morel, who had the idea of developing an automated experimentation platform. Laurent Fabre, assistant engineer at ISIR, was responsible for designing a prototype that met the specifications," explains Eric Lalanne. After several months of work and the necessary readjustments to optimize the ergonomics of the station, a rotating and automated platform that limited repetitive gestures, was finalized in 2019.

Three watchwords: education, science and solidarity

A few months later, the director of ISIR proposed to go further by involving students from Polytech Sorbonne as part of their study project. "Guillaume Morel suggested that we take charge of the development of complementary devices within the robotics speciality", explains Aline Baudry, robotics engineer at Polytech Sorbonne and supervisor of the student projects. "Every year, we offer our fourth-year students the opportunity to work one day a week on concrete industrial projects proposed by people outside the school: robotics manufacturers, companies in other fields, but also surgeons or laboratories that have a specific problem. The students must create a prototype, improve a device or carry out a feasibility study. This enables them to learn about life as an engineer: defining what needs to be done, developing a proof of concept, talking to customers, setting up a team, and more," explains Frédéric Plumet, head of the school's robotics specialization.

In this context, a group of four robotics students began working on a second version of the experimentation platform. They proposed an automated device that enabled the elements used for the tests to be moved on the rotary table using a magnetic arm.

This robotized system is accompanied by a digital interface that enables the user to both manage the movements of the platform, as well as record the monitoring of the experiment and to acquire data automatically. "The aim of the system is twofold: it should further reduce the physical effort involved in handling the platform, but also increase the reliability of the data collected by avoiding human errors," explains neurobiologist Elise Morice, who is closely monitoring the project.

A round table discussion

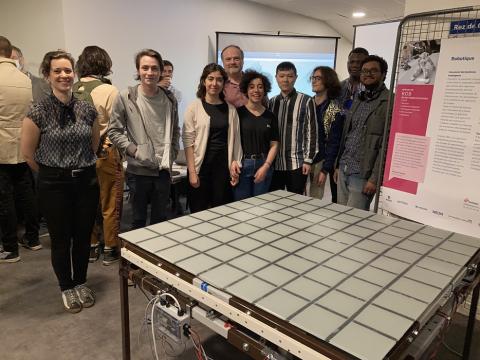

While the students were starting to develop and program the device, the pandemic disrupted the progress of the project. In September 2020, they passed the torch to students in the third-year Student Engagement module, and then engineer Aline Baudry completed the platform, supported by colleagues from other labs. "We worked with the Sorbonne University FabLab to make the wooden track for the chassis that guides the movement of the platform. I also received support from engineers, technicians and machinists from ISIR and LOCEAN, as well as help from teachers and staff at Polytech. It is also thanks to Polytech's prototyping platform, which we manage with Sylvain Viateur, that a large part of the physical creations were made," explains the engineer. “Aline has played a fundamental role in this unifying project," emphasizes Frédéric Plumet. “Both as a supervisor of the student projects and as the producer of the platform."

The new version of the table will be delivered to the neurobiology laboratory next fall. It will not only ease the technician's day-to-day workload, but also to enhance the reliability of the experiment to better understand memory processes in mice.

While this project reflects Sorbonne University's commitment to supporting and including employees with disabilities, it has also helped to create links between the university's various stakeholders, to pass on skills, to unite teams and to stimulate everyone’s creativity.